Climbing to New Heights: A Comprehensive Guide to Industrial Ladders

Ever had one of those heart-stopping moments when you’re perched precariously on a ladder, wondering if it’s sturdy enough to hold you? As someone who’s

Ladders are one of the most useful tools that every organization and household owns. Most people have a basic awareness of what it takes to be safe on a ladder. Yet incredibly, many of the accidents that involve injuries from ladder use come from a lack of ladder safety basics being implemented.

Falls from portable ladders are one of the leading causing of injuries and fatalities in occupational settings. [1]

For workers who use a ladder in the course of their job duties, 1 in 5 fall injuries has involved a ladder. Those who work in construction and aviation are at the highest risk. 81% of fall injuries treated in emergency rooms in the United States have involved a ladder for these workers. [2]

treated in emergency rooms in the United States have involved a ladder for these workers. [2]

These ladder safety basics should be reviewed on a regular basis with all employees, no matter what the occupational setting may be.

By following these basic ladder safety precautions, whether at home or in the course of occupational duties, it is possible to use this tool safely and reduce the risks of experiencing a serious injury.

Choosing the wrong ladder for the job can be a very dangerous proposition. To ensure the correct ladder is being used, it is important to think about the job duties that must be performed. The right size and style will be critical to a safe user experience.

To ensure that the best possible ladder is being used for the job, these three essential questions should be considered every time.

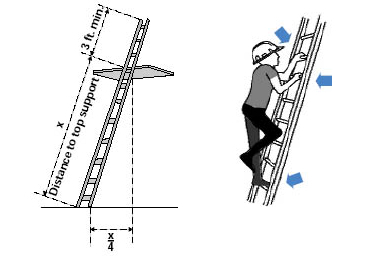

Once you have found the correct ladder, you’re ready to begin using it. You’ll need to make sure that the ladder has a solid and firm surface that is can be placed upon. Surfaces that are either soft or wet can become slippery and increase the risk of an injury occurring.

There are certain best practices that can be followed to ensure that the ladder can be as supportive a tool as possible.

If you do need to place a ladder on soft ground, use a board or a plywood sheet to create a firmer surface underneath the feet of the ladder.

Ladders that have been identified as needing to be repaired are subject to the following rules. [4]

A portable ladder with a structural defect, which includes missing and broken steps, cleats, or rungs, must be tagged with language that states “Do Not Use.” The language must be clearly visible to indicate the ladder has been withdrawn from service. Component corrosion, defective components, and split rails should also be immediately tagged.

Fixed ladders are often used even though a maintenance defect may be present. Any ladder that is covered in water or ice should be temporarily removed from service until the defect can be remedied. Damage from a lack of maintenance can create a long-term gap in alder service

“Do Not Use” language immediately withdraws a ladder from service. Blocking a fixed ladder’s access, such as with a sheet of plywood, is also a method of withdrawing a ladder from service. Both ends of a fixed ladder must be blocked if this option is being taken.

Any repairs that are completed on a defective ladder must be to the standards set forth by manufacturer guidelines. Ladders are considered withdrawn from service until those guidelines are met.

Incorrect placement. Incorrect use. Incorrect ladder choice. Incorrect maintenance.

These are the 4 most common causes of injury that occur when ladders are being used. The risks apply to residential and occupational use of this tool. Organizations which do not promote a culture of safety can place their workers at a higher risk of suffering an accident. That higher risk comes along with a higher risk of liability should an injury occur.

There are steps that can be taken today to limit that risk. Create policies and procedures that take a common-sense approach to ladder safety. Have regular ladder safety training programs. Take damaged ladders out of service immediately.

By being proactive about the basics of ladder safety, there is a better chance that everyone will get to come home at the end of the day.

[1] “Portable Ladder Safety.” OSHA Quick Card. Osha.gov.

[2] “Occupational Ladder Fall Injuries.” Centers for Disease Control and Prevention. April 25, 2014.

[3] “Ladder Safety One Rung at a Time.” National Safety Council.

[4] “Stairways and Ladders: A Guide to OSHA Rules.” Osha.gov.

Ever had one of those heart-stopping moments when you’re perched precariously on a ladder, wondering if it’s sturdy enough to hold you? As someone who’s

Have you ever battled a muddy mess of a driveway after a heavy rain? Or maybe your gravel path constantly seems to wash away. Traditional solutions like gravel or concrete can be expensive, time-consuming to install, and require frequent maintenance. But what if there was a better way?

Enter GeoCell, a revolutionary cellular confinement system that’s transforming the way we build strong, stable, and long-lasting driveways, paths, and even parking areas.

Spring brings fresh beginnings, warmer weather, and the perfect time for decluttering and dusting off neglected spaces. In the world of warehouse organization, implementing genius cleaning tricks can transform chaos into order. This article explores innovative spring cleaning hacks and decluttering tips tailored specifically for warehouses, shedding light on dust off techniques to optimize efficiency and productivity in your storage space.